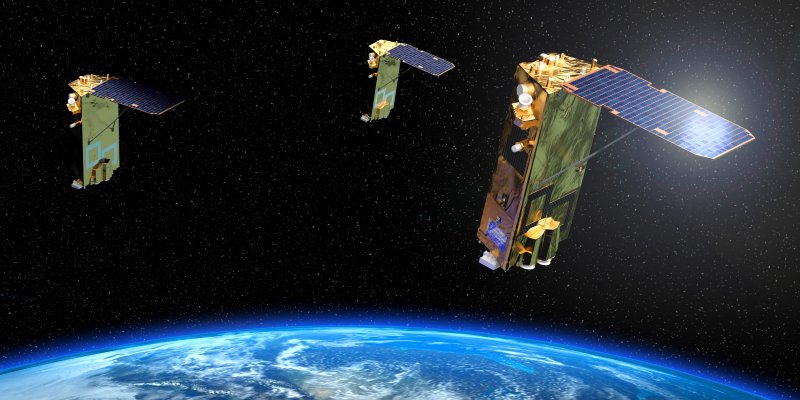

A high-speed camera for monitoring vegetation from space and combating famine in Africa is being adapted to spot changes in human skin cells, invisible to the naked eye, to help diagnose skin diseases like cancer.

In fact, the extraordinary digital infrared sensor from ESA’s Proba-V vegetation-scanning satelliteis being adapted for several non-space applications.

Mounted on a standard medical scanner, the space sensor can help doctors to look deeper into human tissues for detecting skin diseases earlier.

It also has a bright future in industry: it has already been shown to improve solar cell production as well as spotting defective items on production lines.

Leading – edge space technology

The Proba-V camera has such a unique wide field of view that it allows the small satellite to build a fresh picture of our entire planet’s flora every two days.

Developed for ESA by the Belgian company Xenics, the camera sees light we cannot by looking in the shortwave infrared range.

“To humans, two green trees could look similar. But with this camera, we might detect that one is growing well and the other is unhealthy,” explains ESA’s Michael Francois.

On Proba-V, the fresh maps providedon a regular basisby Xenics’s sensor can monitor South America’s rainforest or give farmers in Africa the ability to predict crop yields, for example.

“Based on the experience of preceding years, you can determine whether crop growth is on schedule or behind, and you can get early information on whether there will be sufficient food,” points out Koen van der Zanden from Xenics.

Rigours of space force innovation on Earth

Proba-V’s ability to ‘see the unseeable’ as Earth hurtlespast beneath made the commercialisation of the camera a natural step.

With support from ESA and the Belgian Space Technology Transfer Programme, the Xenics team created ‘Machine Vision’, integrating cameras on inspection systemstoreplace humans in looking for imperfections.

“The high-speed resolution of our ‘line-scan’ cameras makes them ideal for detecting hidden defects on fast-moving production lines, such as bottle manufacturing or sorting different types of plastics for recycling – all of which look similar to the human eye,” explains Koen.

“The items are moving fast, just like Earth spins below the satellite, so by scanning one complete line at a time we can quickly cover the whole area.”

Source: ESA