Today, Maptek is proud to announce our third generation I-Site XR3 and LR3 laser scanners. Smaller and lighter, the new models offer significant improvement in range capability while retaining the reliability and usability we are known for.

Today, Maptek is proud to announce our third generation I-Site XR3 and LR3 laser scanners. Smaller and lighter, the new models offer significant improvement in range capability while retaining the reliability and usability we are known for.

When Maptek first released I-Site Studio software 18 years ago we focused on developing powerful, practical tools for modelling survey data.

Five years on, we trusted our instincts that mine surveyors would readily adopt high end survey equipment combined with our proven smart software, and in 2004 we began building laser scanning hardware. Over the next decade we continually refined our systems.

Compared to the I-Site 8800 series, the latest I-Site XR3 and LR3 laser scanners are 30% smaller and 25% lighter, with 2.5 times faster data acquisition, and offer 25% improvement in range capability. A new high-dynamic-range panoramic camera produces high resolution digital images for geotechnical analysis and geological mapping.

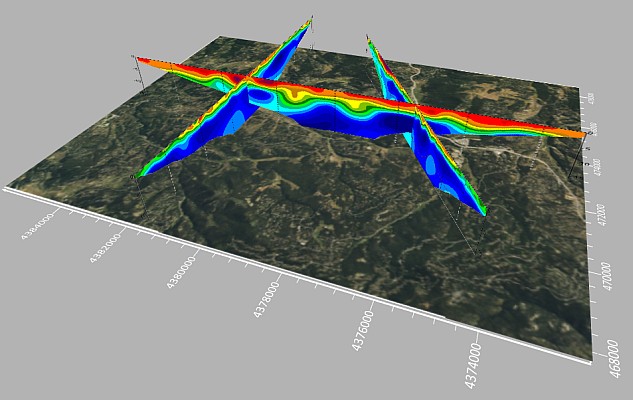

The I-Site XR3 has a scanning range of up to 2400m giving wider coverage with fewer scans and allowing survey of otherwise unattainable areas. The I-Site LR3 scanning range of 1200m makes it the system of choice for small to medium pits and quarries as well as indoor stockpile volumetrics.

‘These new products fulfil our mandate to package survey capability, digital imaging and laser scanning in an easy to use system designed for harsh environments,’ said Jason Richards, Global Business Development Manager Laser Imaging Solutions. ‘I-Site laser scanners remain the only truly mining-tough systems rated IP65 for environmental protection.’

‘Maptek’s business model of developing, selling and supporting our own products is by its very nature customer-oriented,’ continued Richards. ‘Surveyors are asking for ever more compact systems. Site conditions demand reliability and ease of field use alongside increasing flexibility for teams to share operational data.’

‘Our first laser scanner, the I-Site 4400 has stood the test of time. We have in fact just announced ‘end of life’ to the disappointment of at least one customer still using that model productively for mine survey.’

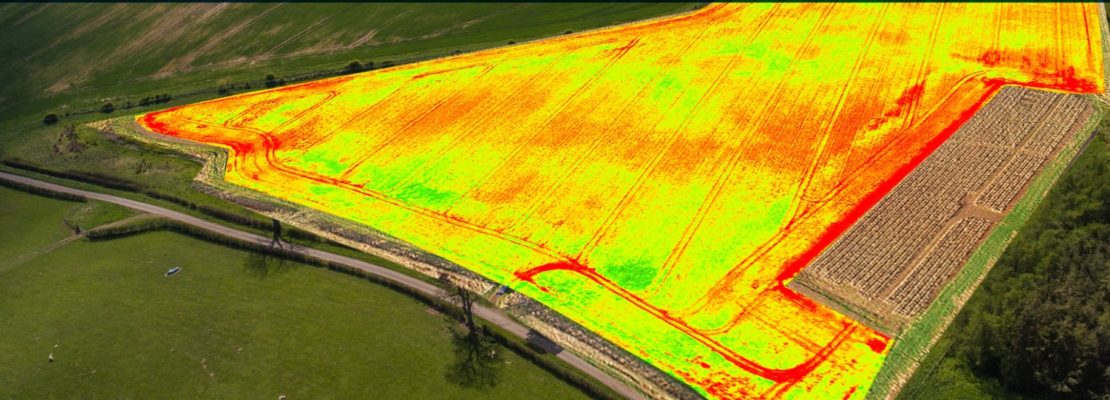

The I-Site XR3 and I-Site LR3 are compatible with laser scanning applications such as Maptek Sentry for surface monitoring and PerfectDig for design conformance. Modular design allows configuration of the system to match site requirements.

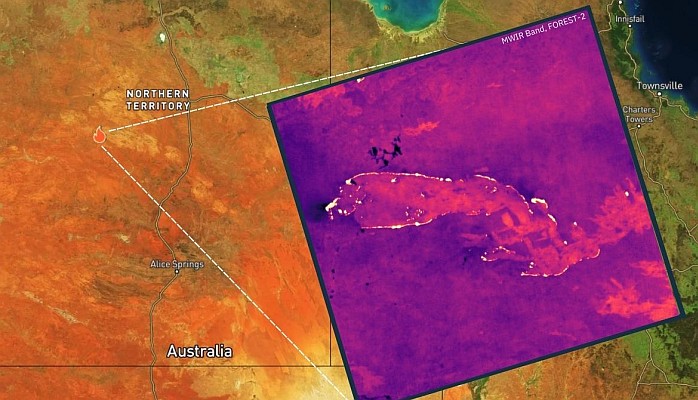

Maptek has also built and launched Sentry as a fully transportable monitoring system. Deployed in a custom trailer, the system offers a power and communications module, cellular and wifi networking, a dedicated, stable bollard for an I-Site laser scanner and proven Sentry software.

I-Site XR3 and LR3 laser scanners are available for order. A unit optimised for underground use, the I-Site SR3, will follow onto market mid-year.

Maptek’s vision is to build products which encapsulate the best in electronics, engineering and design. Mature industry knowledge and strong customer relationships ensure that development beyond 2017 will continue to deliver innovative solutions.

About Maptek

Founded 37 years ago, Maptek™ is a leading provider of innovative software, hardware and services for global mining. Maptek solutions are used at more than 2000 sites in 75 countries, with applications across the mining cycle. Maptek develops industry-leading software Vulcan™, Eureka™, Evolution and BlastLogic™ for mine evaluation, planning, design, scheduling, operation and rehabilitation. I-Site™ is integrated hardware and software for 3D laser scanning, surveying and imaging. The spatial data collected can be used for geotechnical analysis, stockpile measurement, design conformance and movement tracking supported by software systems I-Site Studio, PerfectDig™ and Sentry.