Maptek™ has released I-Site™ Drive to provide mines and industrial operations with a faster, more accurate system for frequent stockpile volume reporting.

I-Site Drive continuously acquires data with recommended I-Site laser scanner mounted on a moving vehicle. Surveyors can quickly measure stockpiles for reporting and comparing daily or weekly volumes, reducing the time for data collection and minimising interruption to site activities.

The Inertial Navigation System (INS) installation in the custom vehicle mount is the key to survey efficiency. It allows the laser scanner to acquire data continuously and automatically assigns real world coordinates to the data, ready for processing. ‘Faster data collection, reduced risk to operators and shorter processing time are key benefits of I-Site Drive’, said Manager of Laser Imaging Systems, Athy Kalatzis.

I-Site Drive is more flexible and affordable than other dedicated mobile solutions. Operations can now use the one laser scanner for tripod, vehicle-mounted stop-go, rail or hatch-mounted survey, and continuous survey. ‘Accurate stockpile reconciliation is easy using I-Site Drive. The same laser scanner handles stockpile volumes, road and pit surveys, pit updates, face mapping and silo volumetrics.’

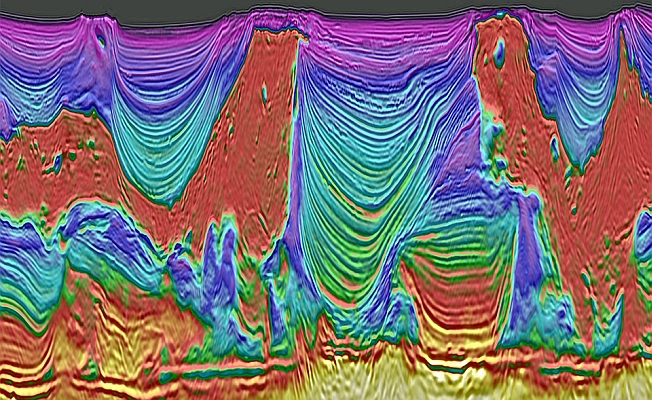

Stockpiles are currently measured by driving around the perimeter with a vehicle-mounted GPS. Volumes are then extrapolated by projecting the angle of the GPS string from the base,’ explained Kalatzis. ‘I-Site Drive links the laser scanner directly with GPS to generate the stockpile profile as it is circumnavigated. The volume is accurately calculated without estimating or inferring from unknown points.’ ‘Maptek customers are already getting excited about the potential uses for I-Site Drive, with drive in-drive out pit surface updates and quick road surveys on their checklist,’ Kalatzis concluded.