Lilium announced last week that it has started assembling the electric propulsion system for its eVTOL, the Lilium Jet. The aircraft, which is expected to perform its first manned flight at the end of 2024, has characteristics that differentiate it from its main competitors in the Advanced Air Mobility (AAM) market.

The term “Jet” is no coincidence. The most common propulsion system in eVTOLs being developed around the world is with propellers, but in the case of the German manufacturer, the bet is on jet propulsion, based on a proprietary technology called Ducted Electric Vectored Thrust (DEVT).

There are 36 electrical ducts with fans and 36 electric motors to provide propulsion. The ducted electric fans are arranged in three pairs on the wings, totaling 12 fan units or flaps. Each front wing has two flaps and each rear wing has four flaps.

In July this year, Lilium completed testing of a full-size prototype Lilium Jet fan and stator at Jetpel’s facilities, one of Germany’s leading aviation technology centers, which confirmed the fan design’s robust operating parameters. Additionally, testing has started on a prototype e-motor, for its mechanical, electrical, and thermal performance. The Lilium Jet e-motor has been designed to deliver industry-leading power density of over 100kW from a system weighing just over 4kg.

Lilium has already tested this system with a prototype called Phoenix 2, which spent several months testing in Spain, being controlled remotely, without any crew on board. These tests were responsible for the company defining the final design of the Lilium Jet, which is now in the assembly phase, both the fuselage and the propulsion system.

Assembly of the Propulsion System

The start of assembly follows extensive testing of propulsion subsystems delivered by suppliers: the custom-designed aircraft e-motor, developed and built-in collaboration with Denso and Honeywell; the titanium compressor fan, developed and built in collaboration with Aeronamic; and electric motor bearings built in collaboration with SKF.

During vertical flight, in the transition between vertical and forward flight, and during forward flight, each flap can tilt independently of the others and operate at different speeds based on wind conditions, resulting in stabilized flight.

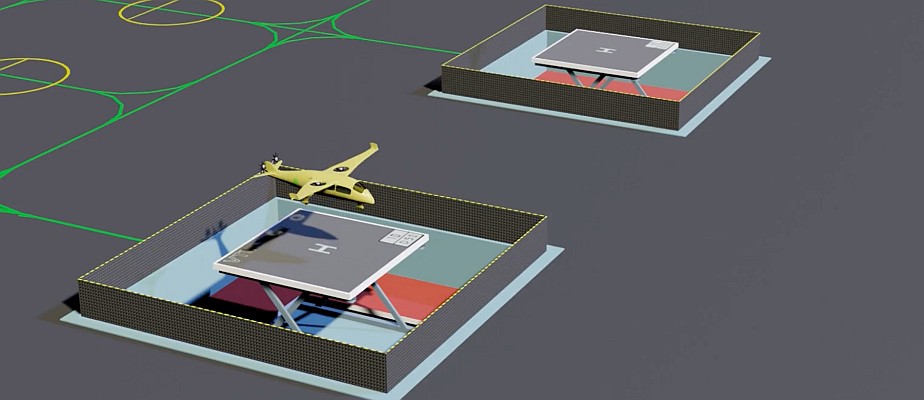

In the first phase of assembly, the propulsion system’s rotating parts, including the shaft, magnets and titanium compressor fan are assembled and mated with the associated static components such as the e-motor stator and guide vanes (for structural support and cooling). These are then integrated into the high performing engine.

In the next phase later this year, the electric engines will be integrated into the Lilium Jet’s propulsion mounting system, the unique flap structure that forms the rear part of the wings and front canards and that houses the propulsion and vectoring systems responsible for vertical and horizontal flight.

“Thanks to the unique propulsion system and aerodynamic jet architecture, I believe the Lilium Jet will set the benchmark for the eVTOL industry, opening the way for superior performance, unit economics and comfort. 95% of commercial airplanes today use jet engines, which offer high safety in addition to the best cabin experience with low vibration and noise, combined with great payload and range potential”, pointed out Lilium CEO, Klaus Roewe.

Lilium’s expectation is that the Lilium Jet will be in commercial operation in 2025. This will also depend on type certification. The process is taking place at the European Union Aviation Safety Agency (EASA) and in parallel at the United States Federal Aviation Administration (FAA), which will allow Lilium to operate in several markets. In Brazil, Azul signed a letter of intent to acquire 250 eVTOLs, but it will also depend on authorization from the Brazilian National Civil Aviation Agency (ANAC) to be able to commercially operate the Lilium Jet.